PVC wall panel and ceiling panel Extrusion Machine

PVC Wall Panel Machine

Product Desription

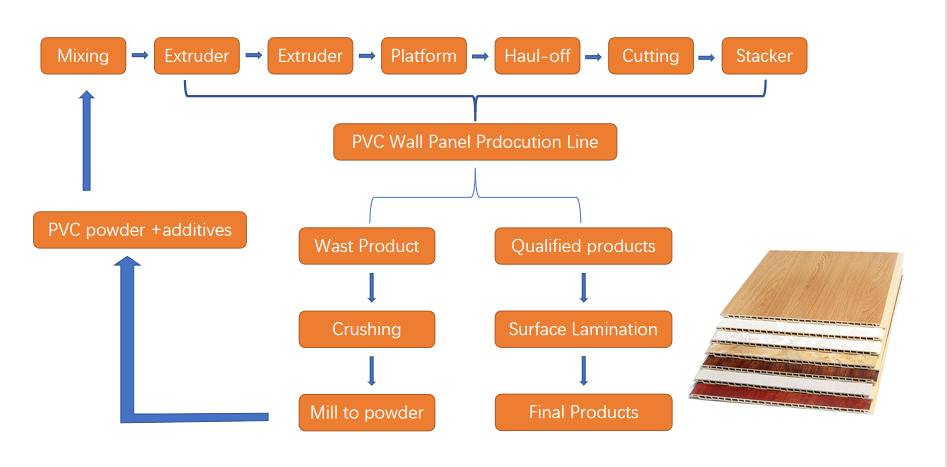

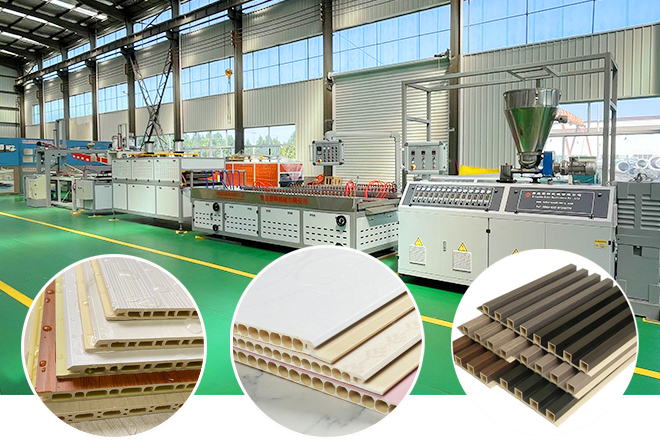

WPC PVC Wall Panel Machine is used to produce PVC wall panel with width normally from 300mm to 600mm with different section shape,the surface of PVC wall panel can be trested by double by hot stamping printing,or by lamination,which can make marble,wooden design on surface of product.

Equipment details

Our hot machine

PVC Wall Panel Extrusion Machine

WPC PVC Wall Panel Machine is used to produce PVC wall panel with width normally from 300mm to 600mm with different section shape,the surface of PVC wall panel can be trested by double by hot stamping printing,or by lamination,which can make marble,wooden design on surface of product.

Final Product of PVC Wall Panel Machine

1. The Thickness and Width:

9mmx300mm,9mmx450mm,9mmx600mm

2. Length specifiation:

3m or according to customer requirement

3. Functions:

Fireproof,Waterproof,Moistureproof,Sound insulation,Heat insulation,

Super hardness,Environmental,Fast and Convenience installation,Easy to clen,

Non-Deformation,Fashion space,Save space ect.

4. Appliction:

Indoor decorate, Shop, Schools, Hospitals, Kitchen , Washing room ,

Hotel , Commercial building, Household decorate ect.

Featurs of PVC Wall Panel Machine

1. PVC wall panel making machine is composed of conical twin-screw extruder, vacuum shaping table, haul-off machine, cutter, turning-up flame.

2. According to the different profile's section and moulds, you can choose different specifications of extruders to fit.

3. The vacuum shaping table adopts special eddy current system to enhance cooling effect.

The unique control skills of horizontal tilt and three dimension regulations embody perfectly for convenient operation.

4. According to the different moulds and shaping tables, you can select corresponding sizing tables to meet the requirement of high output.

5. The tractor uses the unique fluctuation technology and back pressure control with caterpillars around it.

6. The cutter's move speed keeps with the tractor. It can automatically cut for fixed length and it also equipped with powder recycle device.

Technical parameter of PVC Wall Panel Machine

Extruder model |

SJZ65/132 |

SJZ80/156 |

Motor power(kw) |

37 |

55 |

Screw diameter(mm) |

65/132 |

80/156 |

Screw rotation speed(rpm/min) |

34.7 |

34.7 |

Output capacity(kg/h) |

150-250 |

250-400 |

Equipment List of PVC Wall Panel Machine

Twin Screw Extruder

• World famous brand electrical component: Siemens, Schneider, ABB etc;

• High torque gearbox with adopts NSK/SKF bearing;

• Siemens/WEG original motor achieved global after service;

• Bimetallic screw and barrel;

• Intelligent PLC controlling system with human-friendly interface..

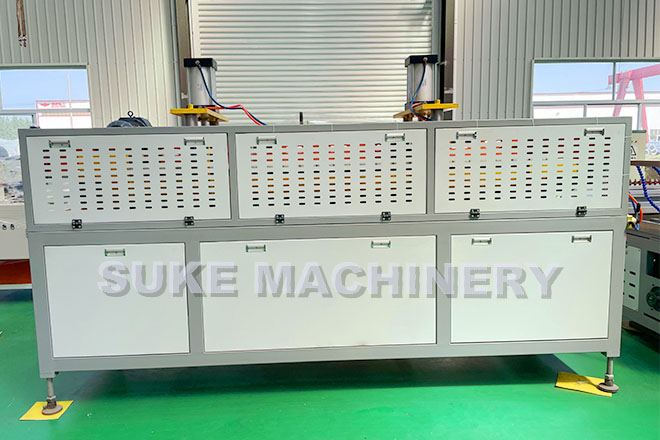

2. Calibration Platform:

Include full set of vacuum and water pump

• Width: 240mm

• Length: 6000mm

• Independent operation panel for easy operation

3. Haul-off machine

• Upper/lower caterpillar driven separately and speed control by inverter

• Fast change type pads for easy operation

• Install plate is adopts aluminum material

4. Cutting machine

• Lifting saw cutter with adopts double station dust collection system

• Synchronous drivingby air cylinder or servo motor control

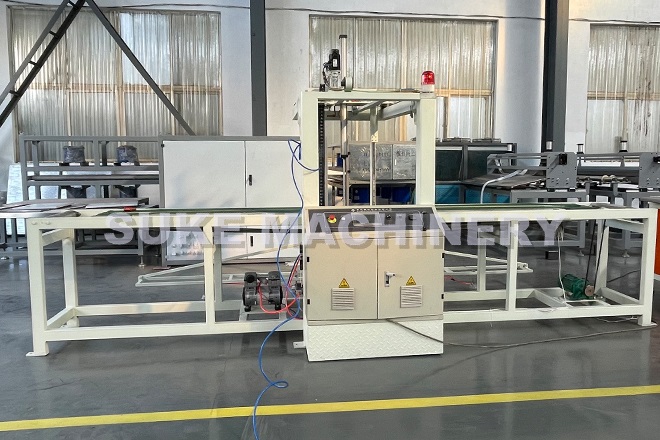

5. Manipulator Stacker

Qingdao suke Machinery Co., Ltd. as a professional manufacturer of plastic extrusion equipment, we have rich experience in PVC wall panel. We are willing to provide professional and targeted plans according to customer needs. Welcome new and old customers to contact us at any time.

Send Inquiry