PRODUCT

PC PP Hollow Sheet Machine

Product Desription

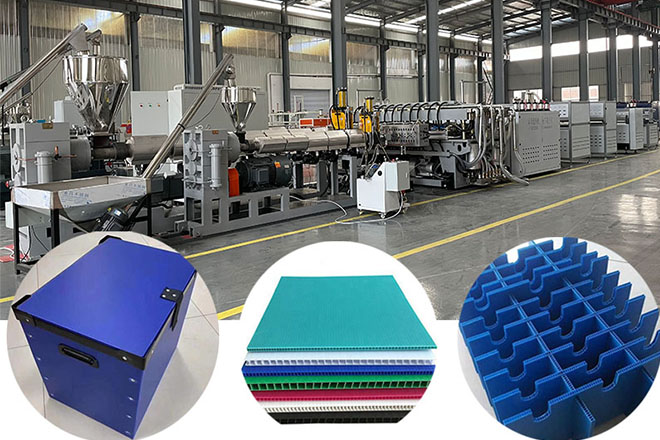

PP/PC hollow sheet machine is suitable for the production of PC/PP hollow grid sheet. PP hollow sheet is widely used in construction, decoration, advertising, road sound insulation, packaging and other industries. PP hollow sheet can also replace the corrugated board of the carton, with light weight, high strength, moisture-proof, anti-corrosion and other characteristics.

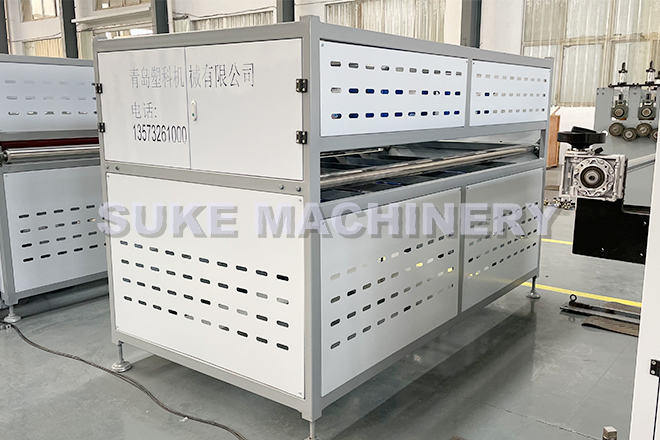

Equipment details

Our hot machine

PP/PC hollow sheet machine(corrugated plastic machine) is suitable for the production of PC/PP hollow grid sheet. PP hollow sheet is widely used in construction, decoration, advertising, road sound insulation, packaging and other industries. PP hollow sheet can also replace the corrugated board of the carton, with light weight, high strength, moisture-proof, anti-corrosion and other characteristics.

PP/PC hollow sheet application:

Packaging field: fruit and vegetable box, turnover box, display box, partition, gift box, food packaging,

Advertising: Political election plastic signs, special event signs, advertising signs, real estate signs, lawn decoration, indoor and outdoor signs

Protect refrigerators and household appliances. Floor protection board,

Stationery, art design and a variety of pattern boxes or exquisite gift bags.

We have all series high quality pc/PP hollow sheet machine ,the width of the products is 1220-2800 mm, and the thickness is 2 mm-12 mm.The extrusion line can reach 2-10 m/min, the high capacity at 200-600 kg/h.We provide high out production line with professional technology support,and auxiliary machine for package box making machines.

No. |

Machine name |

Quantity |

1 |

Material mixing machine |

1 set |

2 |

Single screw extruder |

1 set |

3 |

Single screw co-extruder |

1 set |

4 |

Screen changer |

1 set |

5 |

Co-extruder mold:ABA |

1 set |

6 |

Calibrating machine |

1 set |

7 |

Six-pairs haul off machine |

1 set |

8 |

Preheating Oven |

2 sets |

9 |

Cooling device |

1 set |

10 |

Corona treatment device |

1 set |

11 |

Edge cutting device |

1 set |

12 |

Two-pairs haul off machine |

1 set |

13 |

Transverse cutting machine |

1 set |

14 |

Stacker |

1 set |

| Model | SK1400 | SK1850 | SK2300 | SK2600 | SK3000 |

| Extruder | SJ90x36 | SJ110x36 | SJ120x36 | SJ135x36 | SJ150x36 |

| Max.sheet width | 1250mm | 1700mm | 2150mm | 2450mm | 2800mm |

| Max,output | 200kg/h | 300kg/h | 400kg/h | 450kg/h | 500kg/h |

| Motor power | 75kw | 90kw | 110kw | 132kw | 160kw |

What is the process of producing the PP hollow sheet?

Vacuum loader —> Hopper dryer —> Single screw extruder —> Screen changer —>Calibrator —> 5-roll haul-off machine —>Oven—>Corona unit—> Cooling machine—>2-roll haul-off machine—>Crosswise cutter—>Stacker

Machine details:

1. Single screw extruder

Inverter: ABB/Schneider/Delta

Screw: SJ110/SJ20/SJ150

Motor: 90-132kw

Temperature control : OMRON

Connector: SIEMENS

Screw Feeding.

Uniform Plasticization, Can add more than 60% Filler

2. screen exchanger :

Used for impurity filtration.

Achieve non stop screen changing, it will improve production efficiency, save cost.

3. T-Die Mould:

Final Product width: 1400-3000mm

Heating zone: 13 zones

Forming plate: 2 sets

4. Calibration Machine:

Inlet pipe with valve adjustment

Vertical bar structure, stuffy fire treatment,avoid deformation

central height can be adjusted a little

2sets vacuumed system

5. Haul-off Machine:

two units of hau-off machine

first one has 6 pairs of traction roll

second one has 2 pair of tractron rolll

clamp control by vacuum

Heating Oven Cooling Fan

Cutting Machine:

PLC Control,

Servo Motor

Traction belt moving

Qingdao suke Machinery Co., Ltd. as a professional manufacturer of plastic extrusion equipment, we have rich experience in PP hollow sheet machine. any need, welcome contact with us.

Send Inquiry